Published - 11th Feb 2025

High stakes operating conditions place stringent demands on the supply of energy sector components. Quality, on time delivery and metallurgical excellence are all critical requirements in the manufacturing supply chain. With many years of experience in the sector, and a strong focus on quality and strategic oversight, Investacast and our sister companies in Expromet Technologies Group are well placed to act as your strategic partners for the supply of cast and machined Oil and Gas components.

Expromet Technologies Group manufactures precision engineered cast and machined components for performance-critical Upstream exploration, drilling and production projects. We have a track record of over 20 years supplying the Oil and Gas industry with both standard and bespoke products for surface and subsea applications.

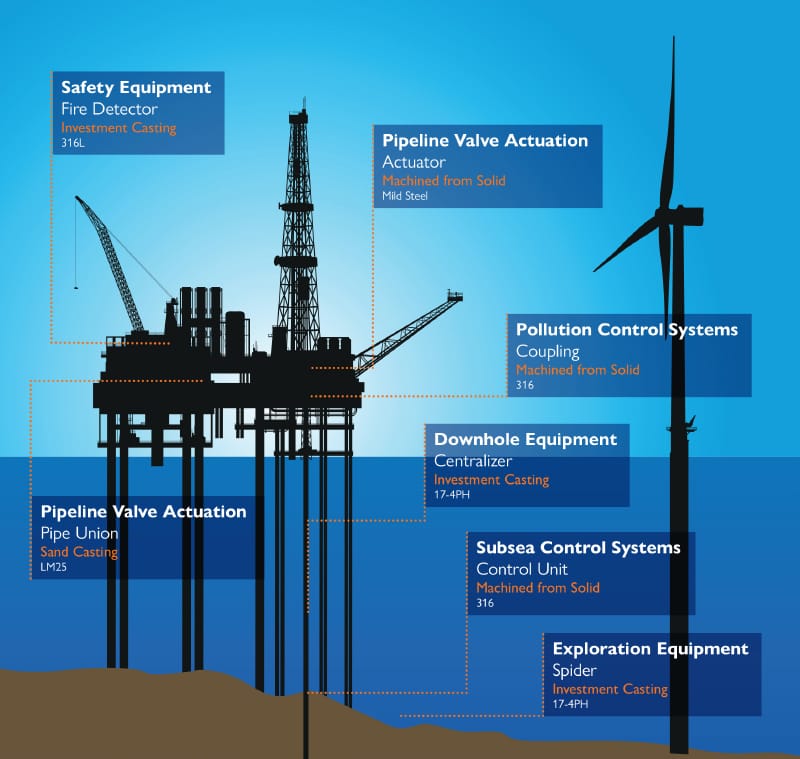

For example, Expromet group companies supply precision engineered components for:

More than a manufacturer, we act as your strategic supply chain partner. By sharing our expertise and delivering high quality components when and where they are needed, we de-risk projects for customers in the Oil and Gas industry.

Consistently high-quality cast and machined components are crucial to the safety and continuity of operations in the Oil and Gas industry. Investacast and our sister Expromet group companies maintain a rigorous process of quality assurance and testing to ensure that our components consistently meet or exceed customer specifications.

Each of our facilities is equipped with state-of-the-art CMM (Coordinate Measuring Machine) inspection equipment, ensuring the highest levels of dimensional accuracy and quality assurance for every component we produce. These advanced systems allow us to conduct precise measurements, validate complex geometries, and meet the stringent tolerances required by industries such Oil and Gas. By integrating cutting-edge inspection technology into our operations, we can guarantee consistency, reliability, and compliance with industry standards, reinforcing our commitment to delivering excellence in every project.

Expromet’s triple ISO certifications (ISO 9001, ISO 14001, and ISO 45001) demonstrate our commitment to quality, environmental management, and occupational health and safety. We also maintain the AS9100 aerospace industry quality management standard for precision machining, underscoring our commitment to providing reliable, high-quality engineered products for the most demanding applications.

It is essential that we deliver components on time to avoid costly downtime in the Oil and Gas industry. Each Expromet company has a firm and tested commitment to on time delivery.

High standards of OTD

Expromet Technologies Group maintains rigorous internal KPIs centred on OTD, which are closely monitored to ensure operational excellence. This consistent tracking allows us to identify trends, proactively address potential bottlenecks, and maintain a strong performance record. Our continuous improvement process integrates data-driven insights directly into our operations, enabling us to refine production schedules, optimise resource allocation, and enhance overall efficiency.

This approach is particularly relevant to the Oil and Gas industry, where supply chain reliability and operational precision are critical. By leveraging robust KPI monitoring and a feedback-driven improvement cycle, Expromet ensures we can meet the sector’s stringent demands, deliver high-quality components within tight timelines, and support the industry’s focus on safety and efficiency.

Stockholding and on-demand call-off

We also offer stockholding and on-demand call-off facilities to streamline delivery and enhance efficiency for our customers. By planning ahead, we ensure you have access to the components you need, exactly when you need them, reducing risks within your supply chain. As your trusted supply chain partner, we optimise stock control by effectively calculating lead times, with replenishment schedules tailored to your specific business and component requirements.

With the addition of Expromet’s new facility in the Philippines, we’ve expanded our global production and warehousing capabilities. Customers can now benefit from our Southeast Asia stockholding and call-off services, along with access to on-site CNC machining and potential tariff advantages.

Each Expromet group company is more than just a manufacturer: we give you access to our extensive technical and metallurgical expertise and work with you as a long-term support partner.

New product development

Our technical team works with you from conceptualisation to design the next generation of Oil and Gas equipment. We use the latest technology to support visualisation and prototyping, and provide support with tendering and quotations to drive projects to full production.

Design for Manufacture

Expromet’s engineering experts have in-depth knowledge of the variety of production methods available, both at our UK facilities and through our approved global partners. We help you identify the optimal manufacturing method for your Oil and Gas components, finding a cost-effective solution that meets your requirements.

Extensive material range

We manufacture and source components from a broad spectrum of materials, ranging from carbon steels to exotic superalloys. We have specific expertise in working with exotic alloys like Inconel, often selected for their ability to perform under extreme conditions. These materials require specialist knowledge to manufacture, particularly in the areas of melting, casting, and machining.

Expromet’s technical teams combine over 100 years of individual metallurgical expertise. We are highly skilled in these processes, giving you reassurance that your component will meet the precise specifications and performance standards required by the Oil and Gas industry.

Expromet’s UK manufacturing facilities and global supply network offer extensive capabilities in casting, forging, machining, and fabrication.

With operations across the UK, an approved selection of overseas suppliers and a new facility in the Philippines, Expromet companies are strategically positioned to serve Oil and Gas customers around the world.

At Investacast and across Expromet Technologies Group, we understand the importance of de-risking your supply chain. We partner with you collaboratively in your Oil and Gas project, aiming to reduce risks while maximising performance. We offer:

If you would like to find out more about our manufacturing capabilities for the Oil and Gas industry, please contact us.

What materials do you specialise in for Oil and Gas components?

Investacast specialises in Investment casting, Forging, Pressure Die casting and Pressings from a wide range of materials suitable for demanding applications.

Why should I choose Investacast for my Oil and Gas components?

We offer exceptional dimensional accuracy, state-of-the-art casting simulation software, precision metal filtration and feeding techniques in investment casting. Engineering excellence, technological advancement and precision are at the core of everything we do.

How quickly can Investacast deliver custom components?

We pride ourselves on our ability to meet tight deadlines. With rapid repair and replacement services and on-demand stockholding, we ensure fast delivery without compromising on quality.

Does Expromet offer support for bespoke Oil and Gas components?

Yes, Expromet specialises in both standard and bespoke components. We work closely with our customers to design and manufacture components that meet their specific needs.

What is the benefit of using exotic alloys like Inconel in Oil and Gas components?

Exotic alloys such as Inconel offer superior strength and resistance to extreme conditions, making them ideal for critical applications in the Oil and Gas industry.

How does Expromet ensure quality in its components?

We hold triple ISO certifications (ISO 9001, ISO 14001, and ISO 45001) and the AS9100 aerospace standard, ensuring that every component we manufacture meets the highest quality standards.

Can Investacast provide stockholding and on-demand services?

Yes, we offer stockholding and on-demand call-off services, ensuring that you have access to essential components exactly when you need them.

If you have a project, talk to our experienced sales team

Contact us