Published - 31st Jan 2022

How Investacast helps you find the right solution

Customers choose Investacast because we provide help every step of the way. From assistance with design and prototyping to selecting the most cost-efficient manufacturing process for your needs, we have the experience to ensure we deliver the best solution every time.

Investacast offers a wide range of manufacturing processes including many casting options, as outlined in An Overview of Casting Processes. But how does a customer select the best option for their part?

There is no simple answer to this question as there are many factors that may determine which solution is best for different applications. Fortunately, Investacast, along with its sister companies Haworth Castings and Metaltech, has considerable expertise and will guide you through the options and advise on the optimum production method for your component.

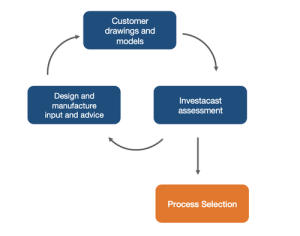

Customers first send us their CAD drawings and 3D product model along with relevant technical specifications so that we can assess their needs.

We work closely with our customers’ engineers to provide feedback on design considerations that may make the parts easier to make and/or reduce the cost of manufacture. By working in this manner, we find the best solution for our customers.

We also liaise with any outsourced supplier to ensure production will meet the final specifications.

The selection of the production process will depend on requirements such as:

The material specification may dictate the manufacturing process, and this is often the starting point – for example only some of the different grades of aluminium can be die cast. If the intended application requires specific mechanical properties and tolerances this may also drive us towards a certain material specification and process selection.

Design complexity

Design complexity and certain technical features may demand specific processes. For example, parts which require undercuts, cores and internal cavities are better suited to casting than machining.

Quality and finish

Where the application demands a specific surface finish or treatment this may affect the choice of process. For example, certain grades of pressure die cast aluminium are not suited to being anodised.

Volume

The size of each order will inevitably have a direct impact on unit price, since many of the more cost-effective manufacturing solutions offered by Investacast require initial investment in a die. For example, a pressure die can cost around ten times more than a lost wax die, but this is quickly recouped in a lower price per part. Where alternative methods are suitable our team will discuss the relative merits with the customer to help them make the choice which best suits their needs.

Speed of production

With its own 3D printing capability in house, Investacast can offer rapid production of prototype or other parts when required and, for every order, turnaround time will be weighed against other factors in determining the best production process.

As we have seen, the best production process for your product will depend on many factors, including the geometry of the part, your specification and material selection, the application or end use, and the required volume and speed of production. At Investacast we use our expertise and the latest technology to help you find the best manufacturing solution. Stay tuned for part 2 of the production method blog, which will detail the pros and cons of different processes.

Contact Investacast for a comprehensive range of world-class engineering solutions for performance-critical applications.

For more information please call +44 (0) 1271 866200 or email [email protected].

If you have a project, talk to our experienced sales team

Contact us