Published - 20th Dec 2023

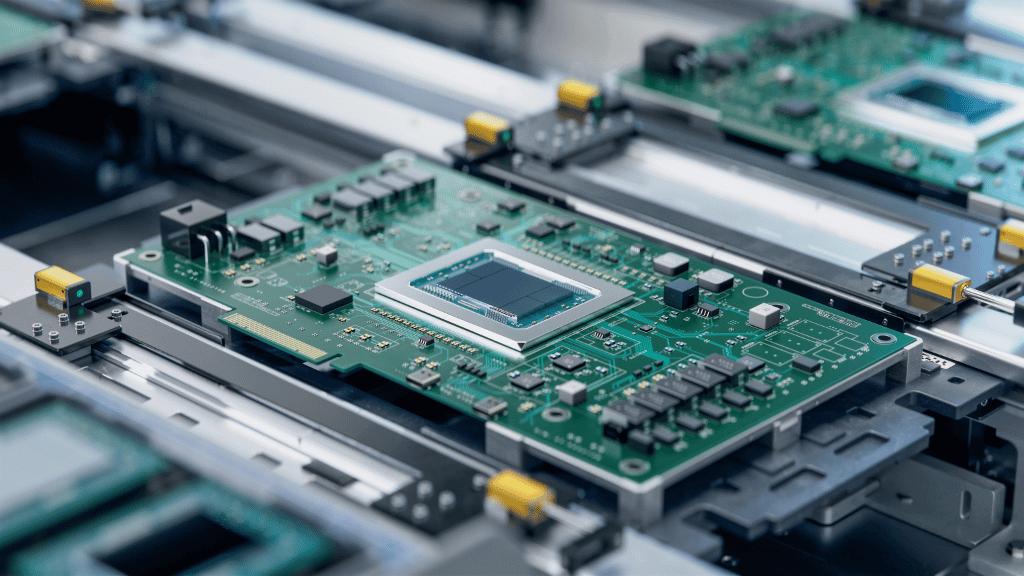

Investacast has extensive experience in the manufacture of close tolerance, high-end nickel alloy castings for use in the manufacturing process for semiconductor chips used in a wide range of industries. In this blog we take a look at how Investacast serves this growing market.

As one of the world’s leading suppliers of investment castings, with a UK manufacturing base in Devon and a global sourcing network, Investacast has supplied castings for the semiconductor industry for over 25 years.

From component design and prototyping through to casting, testing, finishing and stockholding, we supply high quality castings that support the development of semiconductors and their growing use in a wide range of applications.

A semiconductor is a material, such as silicon, used in electrical circuits and components which partially conducts electricity. In a semiconductor chip, the semiconductor lies between the conductor and insulator and controls the flow of electric current in electronic equipment. Semiconductor devices can be adapted for many purposes, such as to show variable resistance, pass current more easily in one direction than the other, or react to light and heat. Uses include the amplification of signals, switching and energy conversion.

Sometimes referred to by their role in integrated circuits (ICs) or microchips, semiconductors are now used in the fabrication of many electronic devices, including computing, automotive and aerospace applications. For example, in automotive applications, software is revolutionising how cars are designed and manufactured to improve aspects such as control, energy efficiency, maintenance and performance.

It is expected that the market for semiconductors will increase by 50% over the next 7 years as microchips are incorporated into everyday products. Investacast has the skills and experience to supply parts that are vital to the semiconductor manufacturing industry.

Investacast makes components for the abatement system, an essential part of the production process which scrubs out waste material. The components are manufactured here in the UK using a specialised process developed at Investacast, one of the few companies capable of manufacturing to the very tight specifications required.

Investacast has years of expertise in nickel castings and uses Hastelloy for the investment casting of weirs for the abatement systems for semiconductor manufacture. Hastelloy is a corrosion-resistant nickel alloy with high temperature resistance and exceptional corrosion resistance, which means that the parts have a longer life span and reduce downtime in the microchip manufacturing process. Nickel alloys can be hard to source, but Investacast has a longstanding relationship with a trusted supplier and is able to react quickly to spikes in demand.

Nickel is also relatively difficult to machine, so over the last 12 months Investacast has invested £500k in new robotic CNC machining capacity in the foundry to gain greater control and efficiency in the post processing of the castings.

With years of expertise and a highly skilled team, Investacast provides a seamless manufacturing and supply process for its customers.

We are heavily involved in new product development and design, which allows Investacast customers to benefit from our extensive experience at an early stage – components will often be developed over a period of 12-24 months. Investacast can also advise on design for manufacture (DfM), and through strong connections to its sister companies in Expromet Technologies Group can provide guidance on the right manufacturing method to ensure the best combination of quality and cost efficiency.

From prototyping through to casting, sampling, testing, finishing and stockholding, we deliver solutions to the highest quality and safety standards, combined with a high level of technical support.

Call us on +44 (0) 1271 866200 or email [email protected] to find out how Investacast can manufacture your semiconductor components.

If you have a project, talk to our experienced sales team

Contact us