Published - 3rd Oct 2022

Improved automation increases product availability for customers

Investacast continues to embrace robot technology to boost productivity, mitigate the shortage of available workers and improve job satisfaction at its manufacturing base in Devon.

In this blog we look at the company’s new automated machine loading cell and the benefits it brings to customers, colleagues and the UK economy.

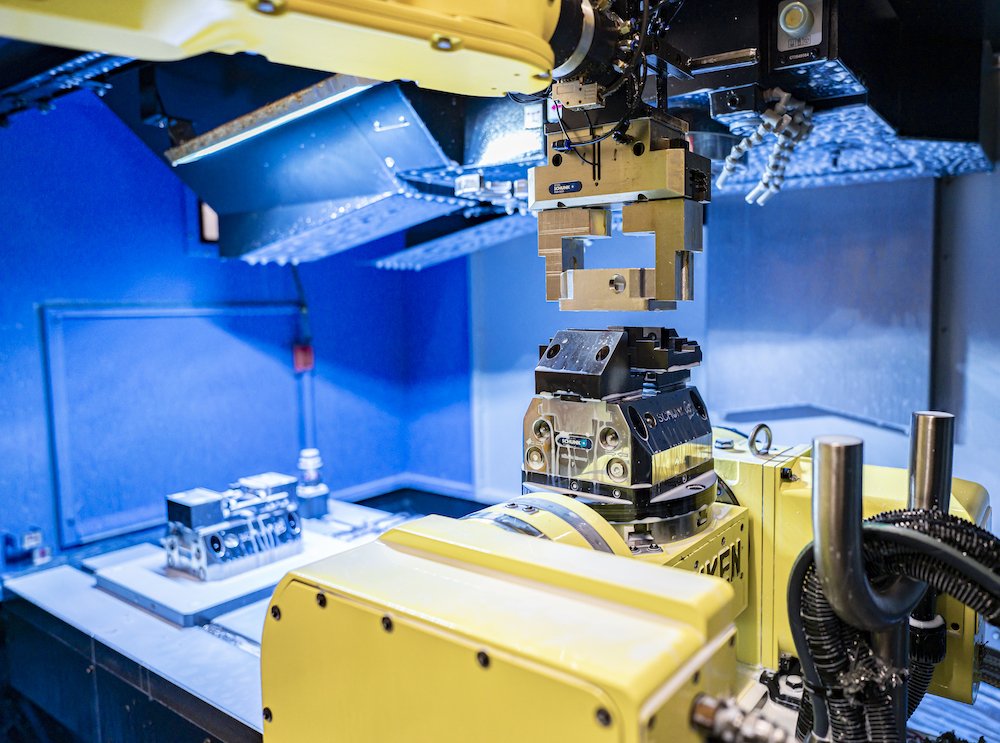

Investacast has used robotics on site for over 20 years, principally in the Shell Room to dip casting moulds into a ceramic coating. However, this new £200k+ investment provides the first robot-fed CNC machine in the company’s CNC machining shop, and marks Investacast’s commitment to automating jobs and improving manual handling.

Robot systems can smoothly manage heavy or repeat loads and medium to large batch quantities that are difficult or repetitive for employees. Once set up to run a specified task, the automated loading cell can continue to feed the CNC machine and could ultimately work 24/7 without intervention.

By making better use of its facility during the ‘lights out’ period, the robot system enables Investacast to increase productivity so customers benefit from quicker response times and a faster turnaround.

The new CNC machine and automated loading cell eliminates the need for continual manual loading of components, which can be heavy and requires constant attention. Machine operators also benefit from reduced contact time with the machines, leading to a lower risk of accidents relating to factors such as moving parts and hot coolants.

“Rather than replacing our workers with technology, we are upskilling them to perform more high-level tasks,” says Chris Thompson, Managing Director at Investacast. “In 5 years, we expect to increase the proportion of employees that are engineers and technicians, with all the benefits that will bring to them and the business.”

Investment in automation and robotics will be critical for the UK to remain at the forefront of global manufacturing and to enable it to compete with lower cost economies. Such investment will contribute to job creation and to the growth of the UK economy.

Rob Porter, Technical and New Products Development Manager at Investacast, says: “Boosting productivity through the adoption of new technologies will ensure ongoing investment and retention of jobs in the UK. Thriving businesses like Investacast must lead the way in safeguarding the future of the domestic manufacturing sector.”

Investacast is proud of its commitment to improving productivity and investing in the future. If you would like to know more about our facilities, including robot fed CNC machining, please contact our expert team on +44 (0) 1271 866200 or email [email protected] for more information.

If you have a project, talk to our experienced sales team

Contact us